PRODUCT LIST

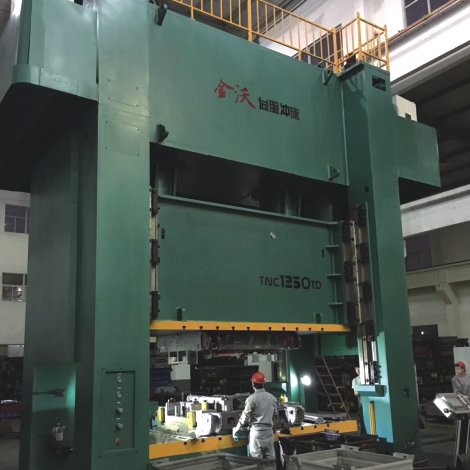

High performance mechanical press

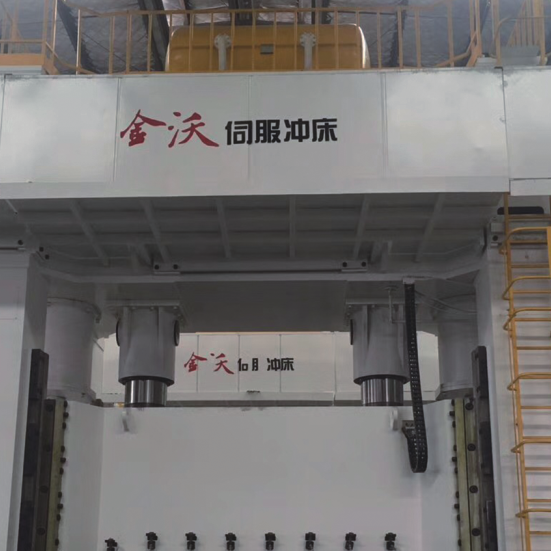

High precision servo press

All-electric servo bending machine

Service Hotline+86 139 6177 5165

PRODUCTS

PRODUCTS

-

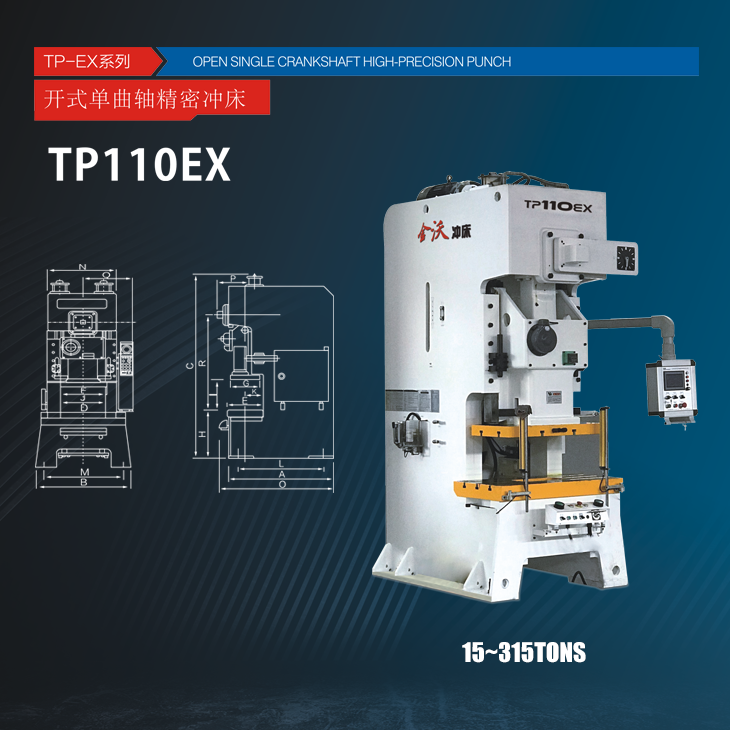

TP-EX series open single crank precision press

TP-EX series open single crank precision press

-

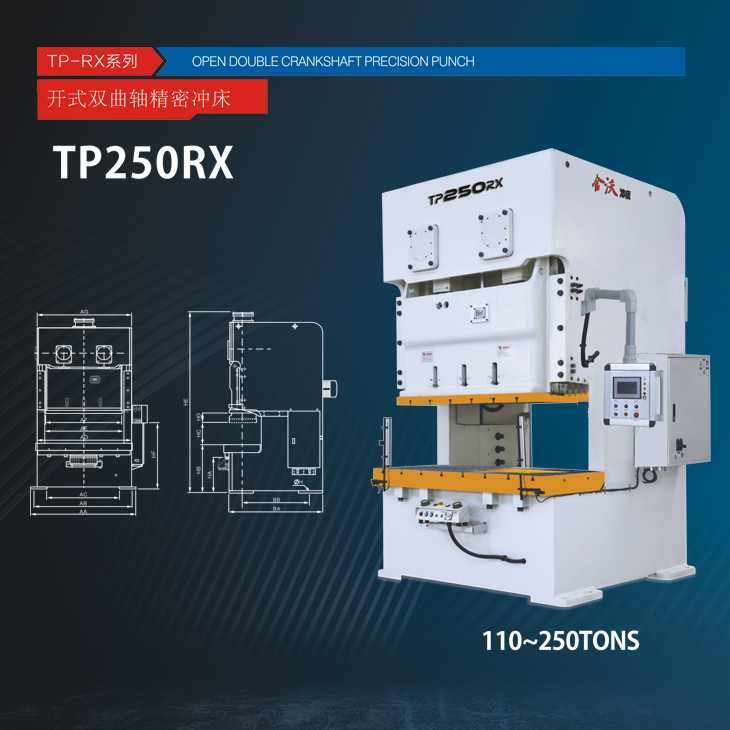

TP-RX series open double crank precision press

TP-RX series open double crank precision press

-

TP-EO series semi-closed single crank precision press

TP-EO series semi-closed single crank precision press

-

TP-RO series closed double crank precision press

TP-RO series closed double crank precision press

-

TP-HX series high speed precision automatic press

TP-HX series high speed precision automatic press

-

TP-HZ series high speed precision press

TP-HZ series high speed precision press

-

TP-ZO series closed single crank precision press

TP-ZO series closed single crank precision press

-

TP-RD series split closed double crankshaft precision press

TP-RD series split closed double crankshaft precision press

-

TP-HD series hot forging press

TP-HD series hot forging press